What’s the Zero-Leak Gold Difference? Read on to see why our plugs and banjos are the best in the industry, then request a free sample to try them for yourself!

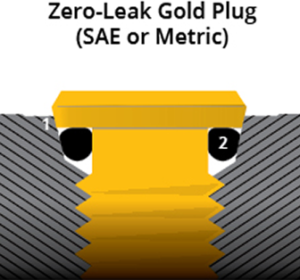

The Zero-Leak Gold Plug employs a very simple, geometry-reliant method of sealing for dependable zero-leak performance in all SAE J1926 and Metric ISO 6149 straight thread port entry plug applications. Available in hexagon and socket head styles, ZLG plugs can be made in mild steel, stainless steel and aluminum in sizes -00 through -32. Any commercially available O-Ring material may be used with ZLG plugs and magnetic plugs, and fully custom plugs are also available for unique applications. All ZLG plugs provide zero-leak performance—guaranteed.

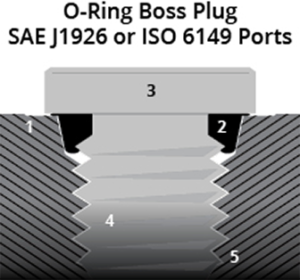

“VIRTUALLY LEAK FREE”

- Port surface must be spot faced

- Larger diameter O-Ring may be extruded out of port creating a possible leak path or be damaged by the threads of the plug and port

- Squeeze fill ratio greater than 100%

- O-Ring extruding and/or shredding

- No backup seal

- High torque required, may strip threads, plug or port

- Poor resistance to vibration – prone to backing out

- May require chemical sealant or tape resulting in possible contamination

GUARANTEED LEAK FREE*

- Plug taper engages with port taper for reliable metal-to-metal seal – spot facing not required

- Smaller diameter O-Ring fits in a recess below plug taper and above threads and acts as backup seal

*Fluid Power Institute Test Data

ZLG PLUG BENEFITS

Zero-Leak Gold Plugs are the most reliable and cost-effective hydraulic fluid sealing options in existence today—all thanks to these unique benefits:

- Two Seals: A primary metal-to-metal seal provides exceptionally high unit loading at the interface of the port and port tapers, which creates maximum gap minimization, and a smaller diameter O-Ring fits below taper contact point for secondary back-up seal protection.

- Effective in vibration, temperature variation and pressure spike environments

- Tapers provide maximum gap minimization

- Allows for wide range of effective assembly torques

- No chemical sealants or tape

- Squeeze fill ratio less than 100%

- Interchangeable with standard straight thread port entry plugs

- Plugs can be resealed repeatedly without loss of effectiveness

- High unit loading

- Low profile design